- Roll & Roller

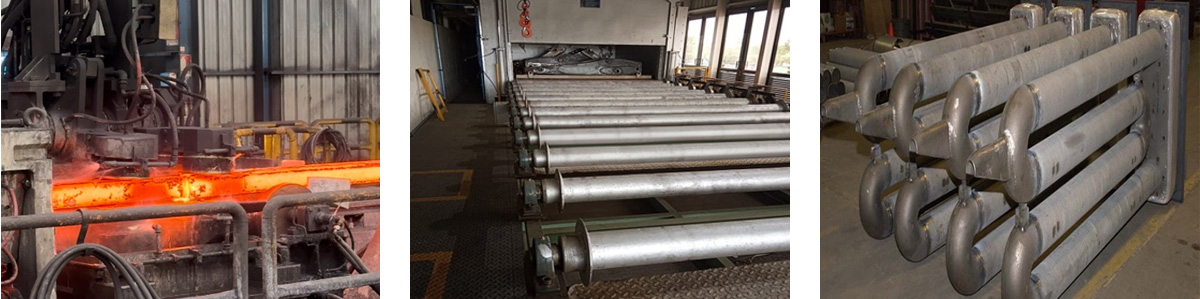

- Casting Roll

- Forged Roll

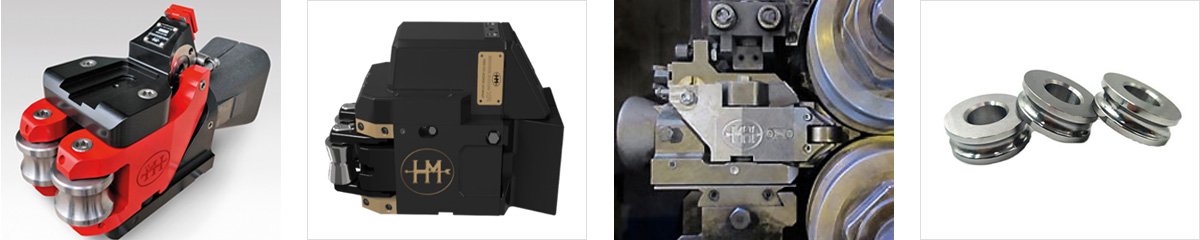

- Tungsten Carbide Roll

- Guide Roller

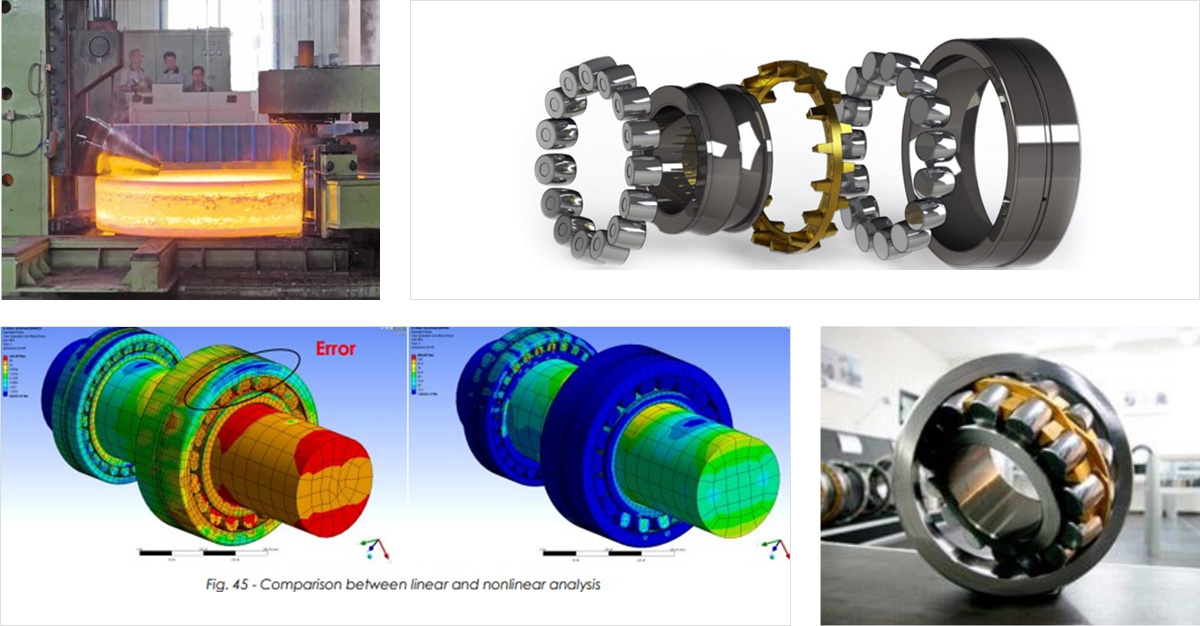

- Bearing

- Straightning Roll

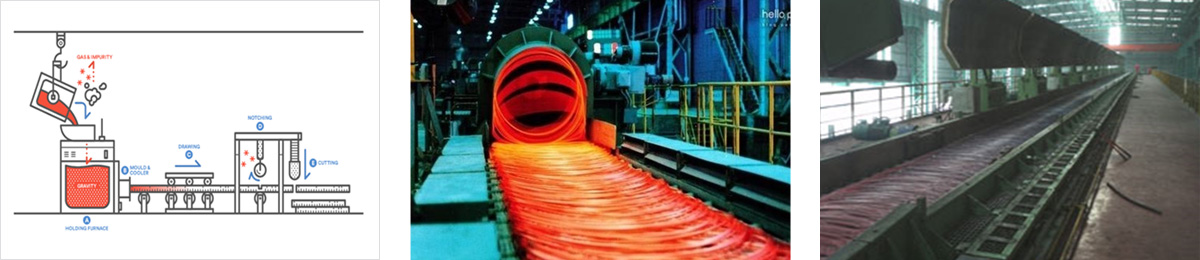

- Stelmor Roll

- Other Roll & Roller

- Equipment & Material

제품소개

MAIN PRODUCTS

Roll & Roller

- Casting Roll

- Forged Roll

- Tungsten Carbide Roll (Ring & Composite Type)

→ Design, Material Selection, Heat Treatment, Assembly, Precision Machining

1. Adamite (ADM)

Hi-Carbon, Impact Resistance, Anti-Wear & Heat Crack

Hardness : HS40~60

Merit : High Toughness, High Load Using

2. Spheroidal Graphite Cast Iron (DCI)

SG Iron, Impact Resistance, Anti-Wear & Heat Crack

Hardness : HS35~70

Merit : Good Surface, High Toughness, Wide Application

3. High Speed Steel (HSS)

MC Carbide & Martensite, Hi-Temp Hardness, Toughness

Hardness : HS70~85

Merit : Good Anti-Wear, Good Surface

4. Tungsten Carbide (초경/TC)

Powder Metallurgy, Good Anti-Wear

Hardness : HS71~99

Merit : Excellent Wear, Good Surface

| Grade | Chemical Composition (Wt%) | Density | Hardness | Transverse Rupture Strength | Compressive Strength | Thermal Conductivity | |

|---|---|---|---|---|---|---|---|

| Binder % | TC % | g/cm³ | HRA | N/mm² | Kg/cm² | sec/℃ | |

| TS8 | 8 | 92 | 14.70 | 88 | 2850 | 4100 | 0.22 |

| TS10 | 10 | 90 | 14.50 | 87 | 2800 | 3900 | 0.22 |

| TS13 | 13 | 87 | 14.20 | 85 | 2700 | 3700 | 0.21 |

| TS15 | 15 | 85 | 14.00 | 84.5 | 2650 | 3500 | 0.2 |

| TS18 | 18 | 82 | 13.70 | 83.5 | 2580 | 3300 | 0.2 |

| TS20 | 20 | 80 | 13.60 | 82 | 2580 | 3100 | 0.19 |

| TS22 | 22 | 78 | 13.40 | 81.5 | 2650 | 3000 | 0.18 |

| TS25 | 25 | 75 | 13.10 | 80 | 2500 | 2900 | 0.17 |

| TS27 | 27 | 73 | 12.90 | 78.5 | 2400 | 2700 | 0.17 |

| TS30 | 30 | 70 | 12.65 | 77.5 | 2300 | 2600 | 0.16 |

| TS30-A | 30 | 70 | 12.70 | 79.7 | 2500 | 2800 | 0.16 |

| Grade | Intermediate | Prefinishing | Finishing | Reducing/Sizing | Screw thread Bars | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | 1 | 2 | 3 | 4 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 1 | 2 | 3 | 4 | ||

| TS30-A | ● | ||||||||||||||||||||

| TS30 | ● | ● | ● | ||||||||||||||||||

| TS27 | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||

| TS25 | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||

| TS22 | ● | ● | ● | ||||||||||||||||||

| TS20 | ● | ● | ● | ● | ● | ||||||||||||||||

| TS18 | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| TS15 | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||

| TS13 | ● | ● | ● | ● | |||||||||||||||||

| TS10 | ● | ● | ● | ● | |||||||||||||||||

| TS8 | ● | ● | |||||||||||||||||||

-

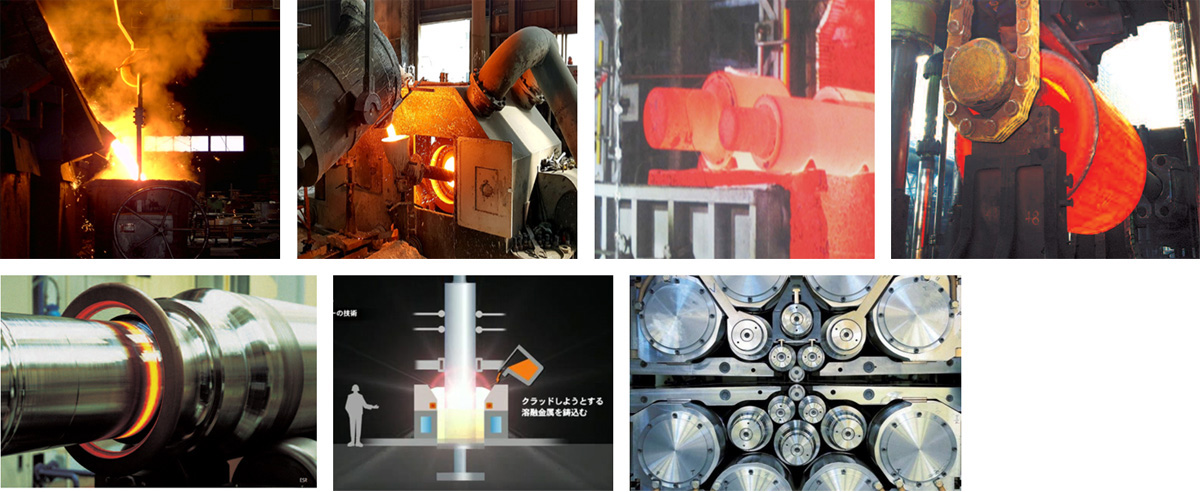

Pinch Roll

-

Looper Roll

-

Transfer Roll

-

Kocks Roll

-

Leveler Roll

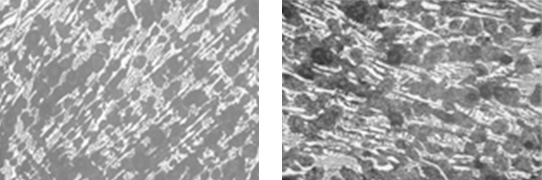

2. Centrifugal Casting

3. Heat Treatment

4. Forging

5. ESR Heat Treatment

6. Hard facing Roll

7. Senzimir Mill

Material Grade choice via considering equipment properties.

Provide engineering and consulting services on case-by-case issues.

- Flat Bar

- Round Bar

- Angle

- Channel

- Inverted Angle

- I Beam & H Beam

- Material :

① Tungsten Carbide

② Titanium Carbide (Fe & Ni Base)

③ Ceramic

④ High Speed Steel (Cast & PM)

⑤ Cast Iron

- Deburring Disk

- Heat Resistance Roller

- Radiant Tube

- Segment Roll for CC

- Transfer Roller

- Run-In-Roller

- Run-Out-Roller

- Roller for Furnace

- High Silicon Ductile Cast Iron

- Horizontal Continuous Casting

- Anti Sticking

- Good Wear Resistance

- High Quality Material

- SHEET-METAL WORKING MACHINES :

- Hot Levellers

- Cold Levellers

- Tension Levellers

- UHTS Levellers

- Flatteners - SHEET FORMING

MACHINES (PRESSES)

AND PUMPS - PAPER

TISSUE AND

CONVERTING

INDUSTRY

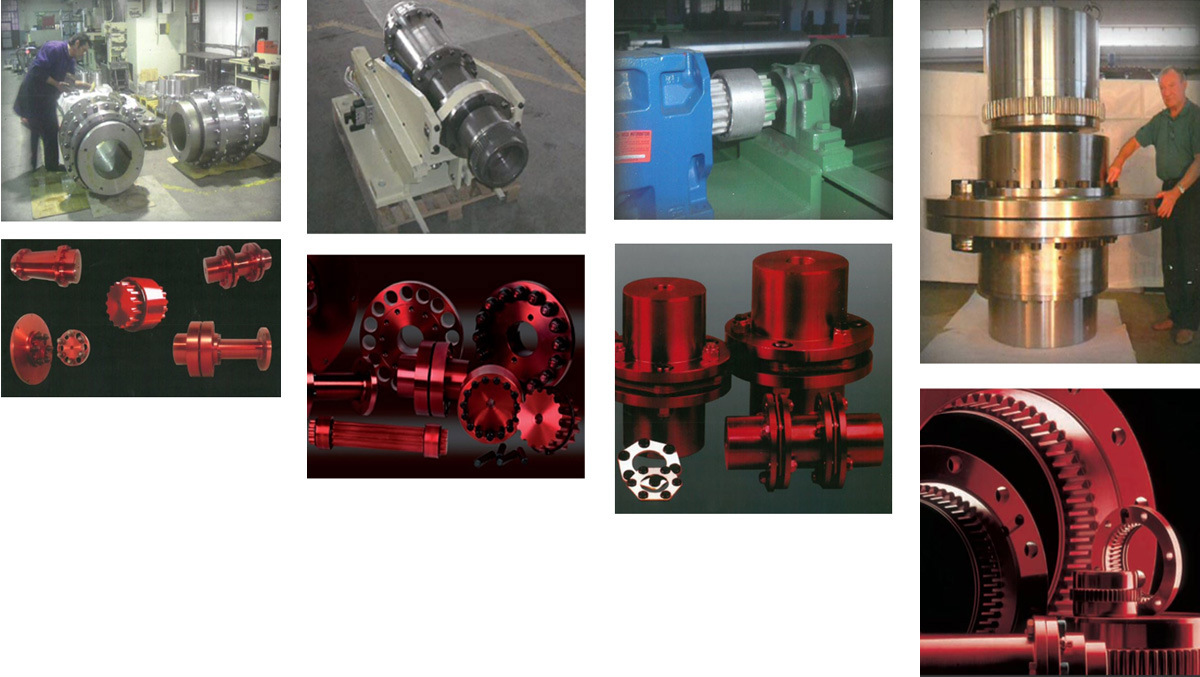

- Work Roll

- IMR Roll

- BUR(Support)Roll

- Eccentric Shaft

- Leveler Cassette

Bearing for Steel Ind., Ship Building, Mining, Heavy Machine Ind

- Application

- Steel Ind.,

- Ship Building

- Mining

- Heavy Machine Ind

- Various Guides

- Roll Chock

- Roll Housing

- Other Steel Structures

- Good Material

- Design Know-How

- Precision Machining

- High Quality Products

→ Power Transmission, Stable Operation